Measurement & Analysis Equipment

Low Viscosity

High Viscosity

Viscosity Measurements for Energy Savings of Fluid Handling Operations

New Fluid viscosity is a key parameter when managing performance and efficiency for quality products. If viscosity is too high, mechanical efficiency is low and that leads to friction, sluggish operation, poor flow to lubricated areas and, in the worst case, cavitation and mechanical failure.

On the other hand, if viscosity is too low and the fluid is too runny, volumetric efficiency suffers and the system becomes less responsive and that hurts productivity. It also leads to overheating, high wear and shorter component life and poor product quality.

By accurately measuring your varying fluid viscosity directly online and in real-time, ELEMENTALE can help you reduce your energy consumption, improve our process operations, realize permanent production efficiencies for increased profitability.

Hydraulic fluids work optimally only within a specific temperature and/or pressure range depending on the type of fluid it is. Viscosity and fluidity have a considerable influence on the quality of the end product.

The viscosity index (VI) is a standardized quantity which takes into account the influence of temperature on the kinematic viscosity.. A higher VI, for example, means less change in viscosity with temperature variations (and vice versa.) That often equates to higher energy efficiency in hydraulic equipment.

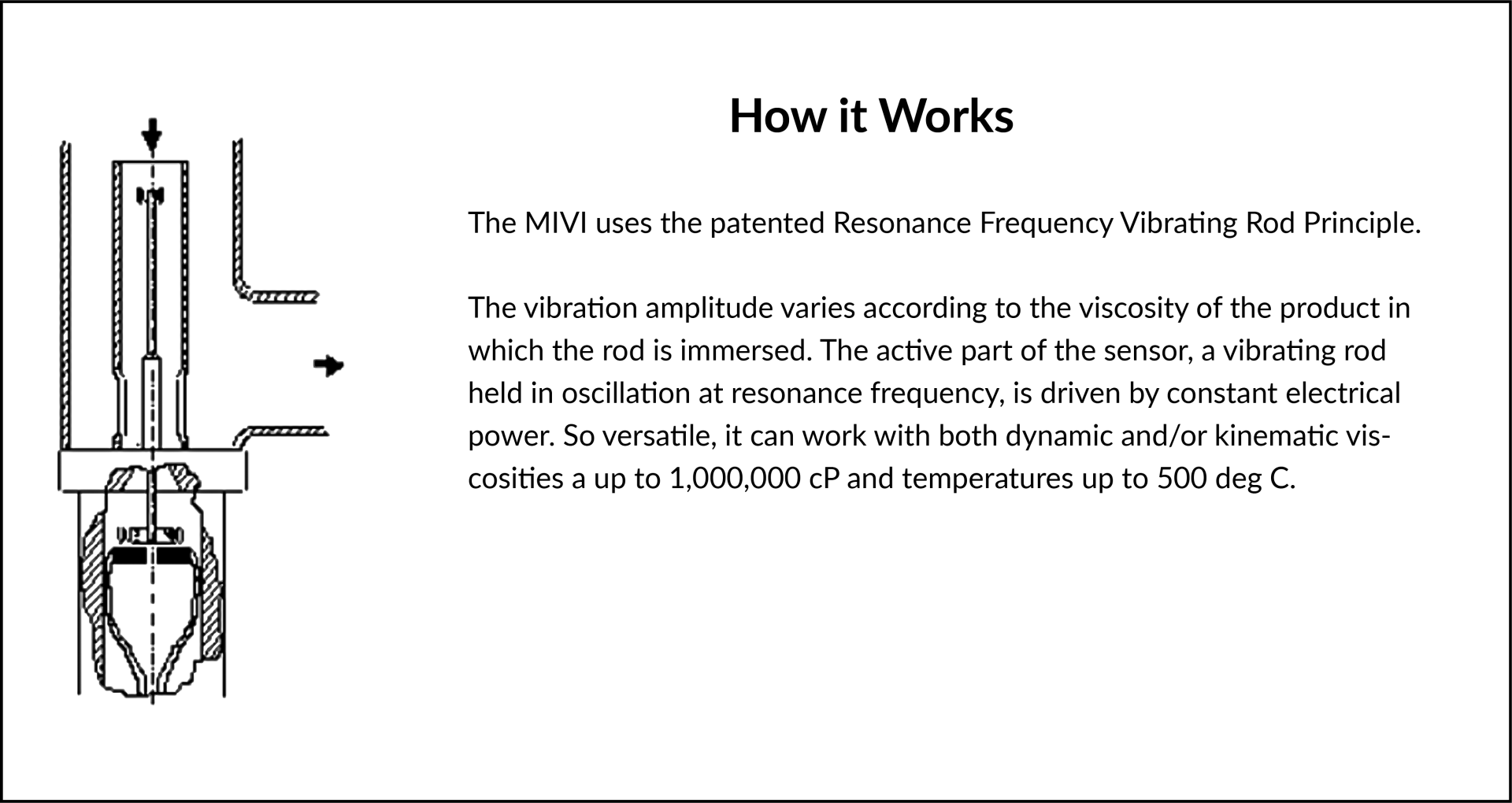

In processes with varying temperature, measurement and calculation of the viscosity index is a real challenge because it is necessary to measure the viscosity of the fluid at reference temperatures and pressures even though the manufacturing process may be at different temperatures. All of the process parameters must be captured to create a representative sample in REAL TIME.

In non-Newtonian fluids, viscosity changes to either thicker or runnier when force is applied.Non-Newtonian fluids are encountered in a wide and varied range of industrial processes including chemicals, polymers, emulsions, slurries, gels, pulp and paper processing to name a few. These fluids regularly exhibit non-Newtonian viscous properties and it is important for the designer to be familiar with the flow behavior of such fluids, how to characterize the fluid’s physical properties and how to use these properties to predict proper flow behavior in process piping systems.

So it’s important to keep viscosity in an optimum range and, thus at its highest efficiency to optimize production and yield maximum efficiency and cost savings.

Please contact us at info@elementale-ent.com to receive a FREE Technical Assessment and quote today!