Cheers to a brand-new year! The Elementale Enterprises team wishes you happiness, health, and success in the year ahead. We’re excited for the opportunities that 2026 will bring and look forward to achieving new milestones together. Wishing you a bright and prosperous New Year!

Company News

As we close out 2025, we reflect on a year filled with progress, innovation, and meaningful partnerships. From attending pivotal industry events like The Hydrogen Tech Expo, BioGas Americas, Analyzer Tech Conference, Gulf Coast Conference, LNG Forum to sharing insights through published articles in Tanks & Terminals, BIC Magazine, BioEnergy Insight, this year has been focused on advancing sustainable solutions and supporting our customers worldwide.

Our team continued to grow, strengthening both our engineering and production capabilities to deliver greater value. We also celebrated milestones like 5 years of Elementale Enterprise Inc., Kylan from Texas A&M Engineering Internship, Sponsoring a Community Outreach to support a wounded soldier.

This year, we forged new partnerships and welcomed top-tier representatives, including Ives Equipment, Adelphi, Northwest Industrial Sales, and Potter-GMH—expanding our reach and delivering innovative technologies to more industries than ever.

We also saw incredible generosity from our team: Yesenia sponsored a veteran and helped rally an outpouring of donations. We were proud to support her family by welcoming a dessert fundraiser as well, helping her niece raise funds for an educational trip to Spain—reinforcing that our impact goes beyond technology and into the communities we serve.

As we step into 2026, we’re excited to build on this momentum—continuing to lead with innovation, collaboration, and a strong vision for a more sustainable future.

To our partners, team members, and customers—thank you for being an essential part of this journey.

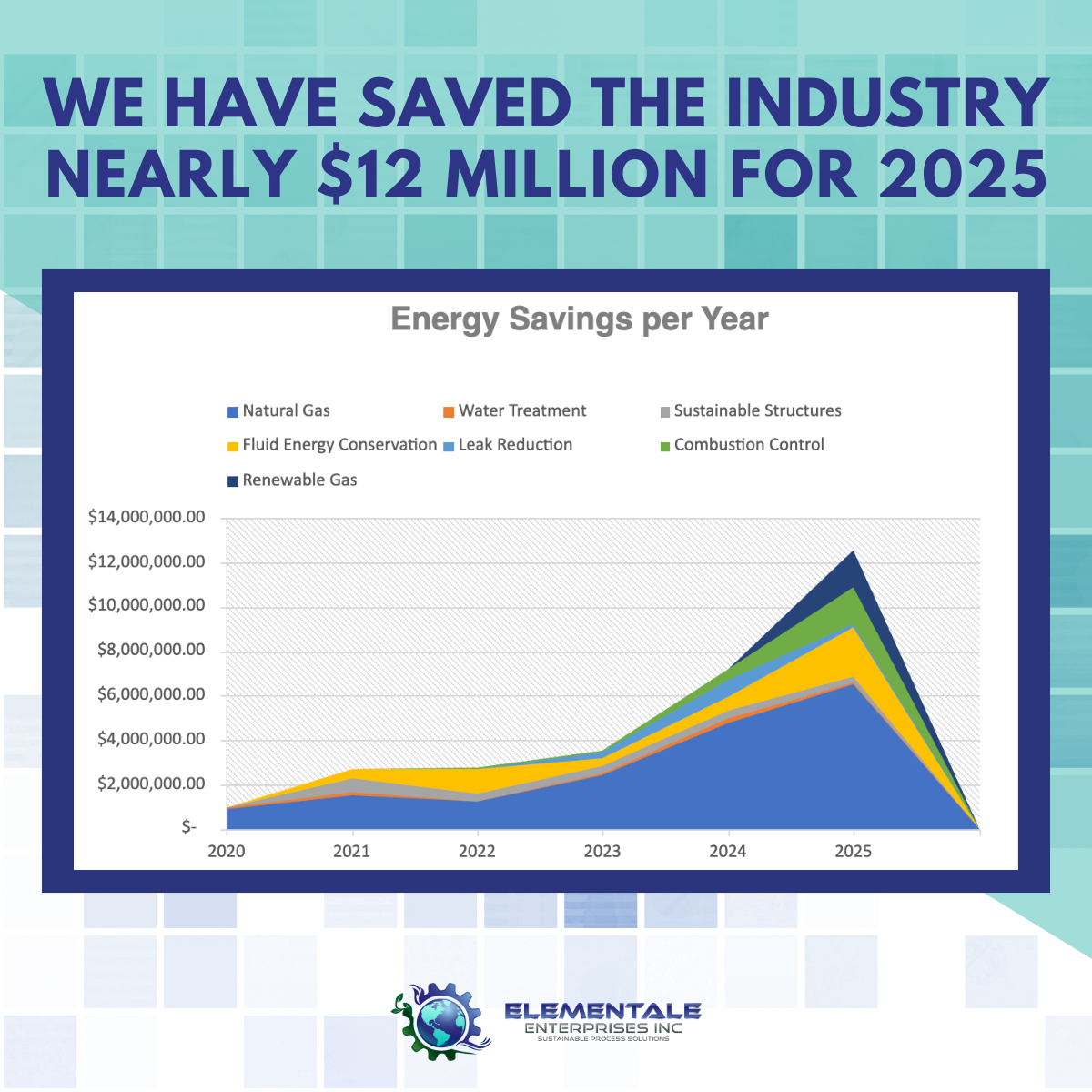

We’re excited to share a remarkable milestone! Through our 2025 projects, we’ve delivered nearly $12 million USD in energy and fuel savings across industries—and nearly $29 million USD since company inception.

This achievement reflects the trust our partners and customers place in us and highlights the strength of our shared commitment to sustainable solutions.

Thank you for being an essential part of this journey. Together, we’re making a lasting impact, and we look forward to building on this momentum to achieve even greater energy and fuel savings in the years ahead!

This Thanksgiving, our hearts are full of gratitude. We’re honored to serve such wonderful customers and truly value the relationships built over the past year. May your holiday season be filled with warmth, joy, and time spent with the ones who matter most. Happy Thanksgiving from all of us to you!

Behind every solution, there’s a team making it happen. From Theresa welcoming you at the front desk, to Yesenia fine-tuning systems in Service, and Xenia engineering smarter designs—every detail matters.

Kim connects with customers as Sales Manager, James leads projects with precision, and Davis brings it all to life in production. Together, this team drives Elementale forward. Grateful for the people who power innovation every day.

When it comes to system integration, every connection matters—and that’s why we trust Swagelok.

From sample systems to fully integrated process solutions, the quality of your fittings plays a major role in long-term performance and safety. Swagelok fittings offer the reliability, consistency, and leak-tight seal we count on—especially in high-temperature, high-pressure, or corrosive environments.

Whether we’re building complex analyzer systems or modular solutions, their components help simplify assembly, reduce downtime, and support our mission to deliver efficient, precise measurement systems.

Proud to work with an industry leader like Swagelok—where better fittings mean better systems.

We’re proud to be a long-time partner with SWAGELOK—an industry leader in making the connections that keep everything flowing smoothly!

This week, our Sr. Project Engineer Xenia Vazquez had the chance to reconnect with Shayne Conde of SWAGELOK right here in our office. They discussed upcoming projects and how Swagelok’s high-quality components and expert support can help us streamline production and stay efficient.

Strong partnerships like this one help us deliver reliable, high-performance solutions every time.

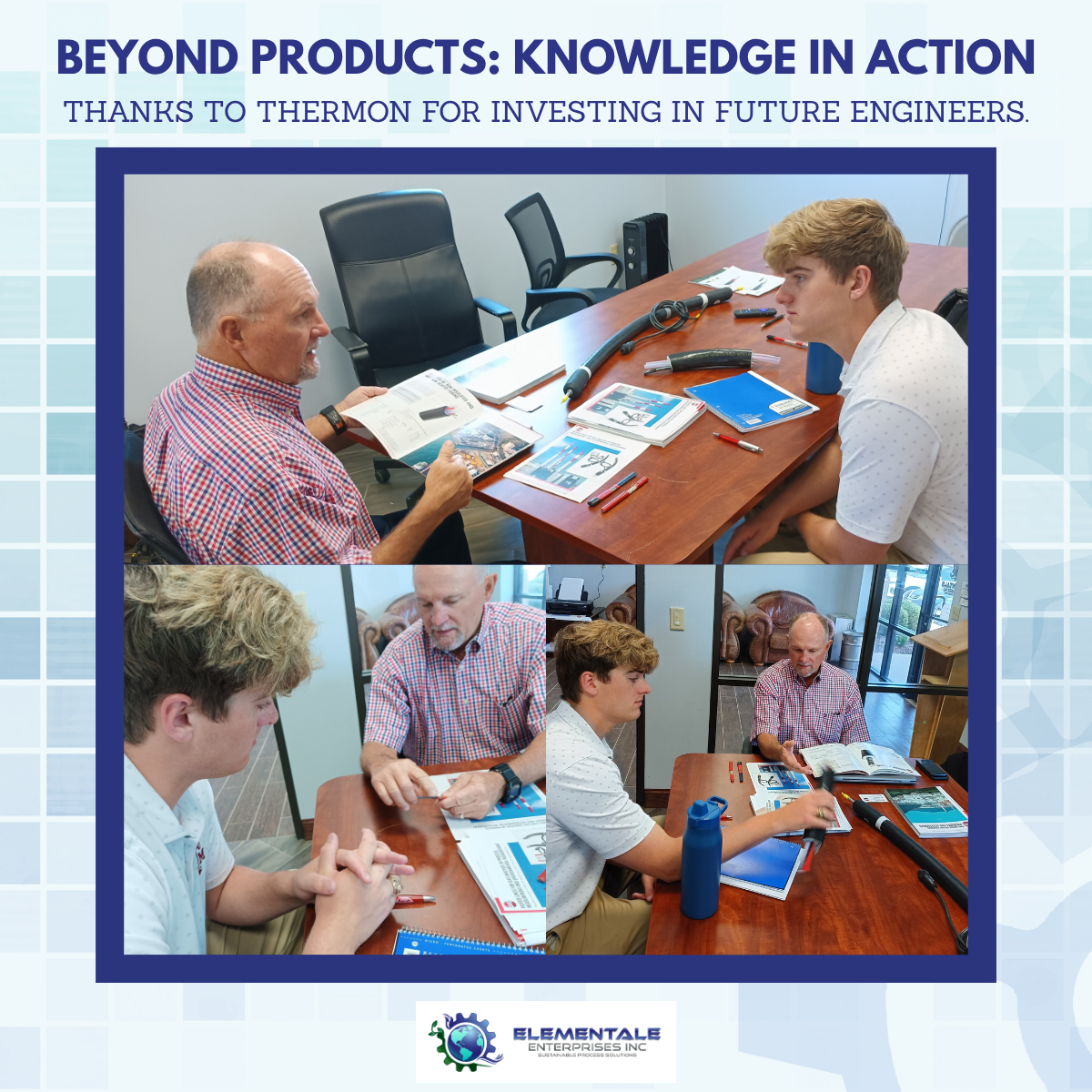

It’s not just about products—it’s about knowledge, innovation, and partnership.

John Mattingly with Thermon met with our team this week and took time to train our Texas A&M intern Kylan Williams on the finer points of proper heat-trace selection. From performance benefits to system complexities, this was more than a sales meeting—it was hands-on education in smart technology and thoughtful problem-solving.

We value partners like Thermon who go beyond the basics and align with our mission: helping customers make informed, efficient, and innovative decisions every step of the way.

Thanks again, John, for investing in the next generation of engineers and sharing your expertise!

We had a great time meeting with our partner Saginaw a few weeks ago!

They’re more than just a supplier—they’re problem solvers who aren’t afraid to think outside of the box to get us exactly what we need. Their enclosures help protect our systems in the toughest conditions, and their creativity and support make all the difference.

Big thanks to Billy Comfort from Saginaw Enclosures for always bringing smart, reliable solutions to the table. We’re grateful for the partnership!

At Elementale Enterprises, innovation isn’t just a buzzword—it’s how we work.

Our engineering team is constantly thinking outside the box to design, test, and implement smarter, faster solutions. One of the ways we stay agile!? 3D printing.

By creating in-house mock-ups of late components, we’re able to simulate system layouts, test fit and function, and keep projects moving forward—even before the actual parts arrive.

It’s a hands-on solution that helps us stay on track, on budget, and ahead of the curve.

Recently, we celebrated with one of our key partners, Anthem Technology, with a big thank-you (and of course donuts)!

Their I.T. expertise plays a critical role in keeping Elementale Enterprises cyber security compliant, ensuring we meet the strict security protocols our customers require.

From maintaining secure infrastructure to supporting our ability to integrate advanced technologies (including AI), Anthem helps lay the foundation for our continued progress.

Here’s to the behind-the-scenes tech that helps drive our mission forward—strong, secure, and smarter than ever.

Please join us in welcoming Kylan Williams to Elementale Enterprises for his summer internship!

Kylan is currently studying Industrial Engineering at Texas A&M University and will be working alongside our team this summer with a focus on Supply Chain Management and Production.

We’re excited to support his growth as he gains real-world experience optimizing processes and contributing to the high standards we hold in our operations.

Welcome to the team, Kylan—we’re proud to have you with us this summer!

Kim and Debra from Elementale Enterprises had a great visit to the Control Instruments factory!

We were thrilled to meet new members of their growing team and reconnect with senior leadership. After our visit, we joined them at a customer-hosted technical seminar focused on the differences between FID and FTA technology.

The energy in the room was contagious—the passion behind the presentation truly sparked valuable conversations.

We’re grateful for the partnership and always inspired by the commitment to innovation, education, and collaboration.

Meet Davis Moody, our dedicated Production Technician here at Elementale Enterprises!

Davis plays a key role in bringing our systems to life—ensuring every component is assembled, tested, and delivered with the precision and reliability our customers count on. From day one, he’s brought a strong work ethic, attention to detail, and a team-first attitude to every project.

Whether he’s troubleshooting a complex system or keeping production on schedule, Davis is an essential part of what makes our operations run smoothly.

We’re grateful to have him on the team!

What started as a small team with a big vision has grown into a trusted name in engineering solutions. Over the last 5 years, we've:

✅ Helped save the industry over $17 million

✅ Partnered with countless clients, reps, and companies across the world

✅ Grown from a handful of employees to a strong team of 10+ and counting

Diverse Installations in O&G, Pharmaceutical, Food & Beverage, Construction, & Commercial Sectors

✅ Even welcomed a foreign exchange intern from France, bringing global perspective to our work

We're proud to deliver smart, safety-driven solutions that optimize performance, protect infrastructure, and drive measurable results.

Thank you to our partners, customers, and team for making this milestone possible. Here's to continued growth, innovation, and impact!

With over 5 years of hands-on experience in analyzer maintenance and process instrumentation, Yesenia brings a sharp technical skillset and a passion for precision to every project she tackles. Her deep understanding of industrial systems and commitment to quality make her a perfect fit for Elementale’s mission of delivering reliable, high-performance solutions.

We're excited to have her on board as we continue to grow and innovate in the world of specialty chemical analytics.

Welcome to the team, Yesenia — we’re lucky to have you!

We’re excited to have two insightful paper presentations at the Analyzer Technology Conference, diving into cutting-edge advancements in analytical measurement.

🔹 Eric Colinet from APIX Analytics will present a paper on Gas Chromatography (GC), exploring how compact and high-speed GC technology can enhance process analysis with greater accuracy and efficiency. This session will highlight real-world applications where fast, precise measurements make a significant impact.

🔹 Luc Belliere and Stéphane Millet from Sofraser will present on viscosity measurement, discussing advanced viscometry techniques that improve process control and quality assurance in industrial applications. Learn how continuous viscosity monitoring leads to better product consistency and operational efficiency.

Don’t miss these expert insights on the latest innovations in analytical technology!

Join us at the Analyzer Technology Conference in Galveston, TX, from April 28 – May 30 to experience live demos of our cutting-edge analyzers in action. This is your opportunity to see our technology firsthand, ask questions, and connect with industry experts.

Don’t miss the chance to explore the latest advancements in analyzer technology—see you there!

>>> Tickets are required for this event and can be purchased at https://www.analyzertechconference.org

Join us at BIOGAS Americas in Denver, CO from April 28-30th! Stop by our booth to discuss how NEMS-based Micro Gas Chromatograph (GC) helps your business become more innovative and precisely measure a variety of gases.

We can't wait to see you there!

We’re excited to announce a remarkable milestone! Through our 2024 projects, we’ve driven nearly $7.7 million USD in energy and fuel savings across industries and nearly $17 Million since company inception. This achievement reflects the confidence our partners and customers have placed in us and underscores the strength of our shared dedication to sustainable solutions.

Thank you for being an essential part of this success. Together, we’re making a lasting impact, and we look forward to building on this momentum to deliver even greater energy and fuel savings in the years to come!

Our latest article, featured in BIC Magazine, explores the transformative role of hydrogen as a sustainable alternative to natural gas in thermal processing and manufacturing. From blending ratios and burner designs to emissions control and safety, we outline the critical factors for implementing hydrogen fuel management systems.

At Elementale Enterprises, we specialize in guiding organizations through these transitions—helping you select the best technologies, optimize processes, and meet your safety and ESG goals.

Read the full article now and discover how we can help you embrace a cleaner, hydrogen-powered future!

Today, we celebrated Stephane's incredible contributions during his year-long internship advancing viscosity solutions with us. His expertise, dedication, and teamwork have made a lasting impact, and we're thrilled that this isn’t goodbye—Stephane will continue collaborating with us from Sofraser in France.

We’re excited to see all that you’ll accomplish in France and look forward to continuing our partnership! ??

Elementale Enterprises is proud to announce that we shipped multiple Sample System Shelters last month, supporting diverse energy-saving initiatives across the industry. These projects included:

- Flare Optimization

- Midstream Management

- Landfill Gas Utilization

- Wastewater Abatement Measurement Systems

Each system is designed to provide precise, reliable measurements for essential environmental and energy-efficiency applications. Our team keeps it simple yet effective, focusing on seamless system integration to meet each project’s unique needs. At Elementale, we’re dedicated to advancing sustainable solutions with systems that prioritize accuracy, efficiency, and long-term value.

We're proud to welcome Northwest Instruments and Controls as our official sales representative for the Northwest USA! Specializing in Process Instrumentation and Measurement Solutions, their team brings top-tier expertise to meet the region's needs.

We're excited for this partnership and look forward to great things together!

Join us at the Plastics Recycling World Expo in Cleveland, Ohio from November 13-14! Stop by our booth (R248) to see how we can help you optimize fluid viscosity, enhance mobility, and minimize energy demands for temperature-varying, viscous fluids.

Stop by and ask us about solutions offered by Elementale Enterprises specifically for viscosity control in high-viscosity polymer production!

We can’t wait to see you there!

>>> Register online HERE

Check out our article, "Beyond the Leak," where we delve into innovative methods for protecting metal components from corrosion.

Explore alternative solutions that go beyond traditional approaches and discover how these techniques can enhance durability and extend the lifespan of your structures. Don't miss out on valuable insights—read the full article here!

Exciting News! We've partnered with IVES Equipment to increase sales of our online process viscometers in the Mid-Atlantic States. With IVES' technical expertise in online process measurement, we're bringing Sofraser's advanced viscosity solutions to the marketplace!

Discover our insightful feature in BioGas magazine, delving into cutting-edge measurement technologies aimed at meeting the stringent standards of the U.S. EPA's 40 CFR 80 "set rule."

Explore our featured article spanning pages 36-38 HERE!

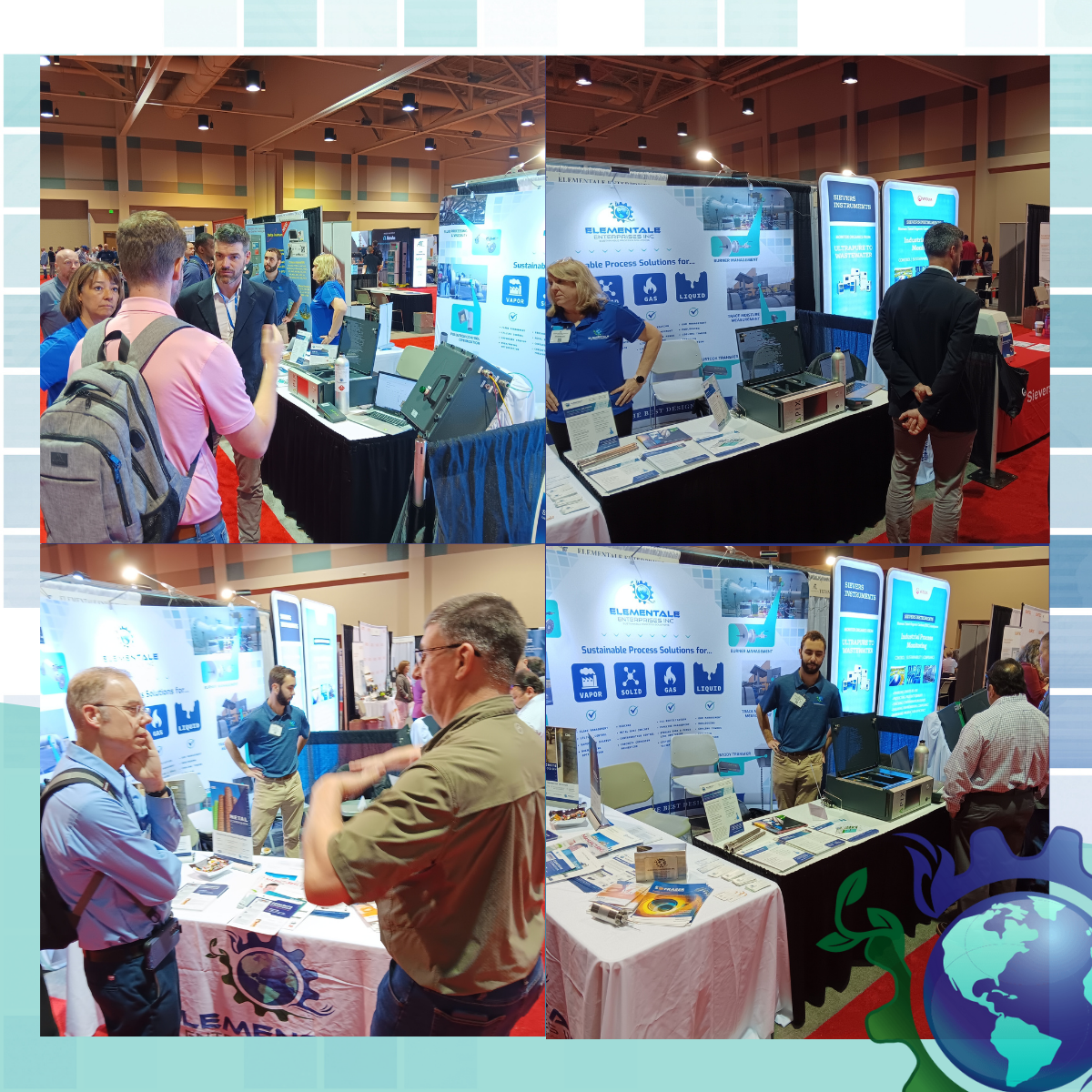

Thank you to everyone who joined us at the Environmental Trade Fair & Conference! We enjoyed connecting with everyone and addressing all the insightful questions you brought to the table!

If you missed the conference, feel free to reach out with any questions you may have! Email us at info@elementale-ent.com

Join us for the Environmental Trade Fair & Conference (ETFC) from May 14th - 15th at the Austin Convention Center in Austin, TX (Booth #1456).

We’ll be there to discuss all the ways we can help you save money through energy conservation, streamlining your industrial process, waste management, and so much more.

At Elementale we provide value-added sustainability engineering solutions in both industrial and commercial areas, that allow them to maintain their competitiveness while staying sustainable.

Register early to save money! We can’t wait to see you there!

We had a blast at the Analyzer Technology Conference, where we showcased our cutting-edge APIX online gas chromatograph, Calorval BTU analyzers as well as our MIVI Inline Viscometer!

Our live demos allowed attendees to experience these firsthand, witnessing their precision and performance in action.

A massive thank you to everyone who joined us at the event!

Elementale Enterprises will be at the Analyzer Technology Conference in Galveston, Texas, and we’d love to see you there! (Booth #309)

This is a great opportunity to see our analyzers in action with live demos and get all your questions answered!

It all takes place April 15 - 19 at the Galveston Island Convention Center.

*Tickets are required for this event and can be purchased here

>>Tuesday is free admittance to the exhibition hall for end-user customers, local techs, retirees, and students! (Check out the conference website for details.)

We can’t wait to see you there!

We're thrilled to announce that Potter GMH has joined our sales team for Southern Califonia.

With their expertise in Industrial automation, they will be working with us to sell our gas detection systems and online viscosity measurement solutions.

We look forward to working with you to provide top-notch innovation to this region.

We’re thrilled to welcome Stephane to our team for the year! He is a recent graduate with his Master’s Degree in Mechanical Engineering, serving a one-year Foreign Exchange program here in the USA specializing in Viscosity Solutions.

We're excited to host Stephane and eagerly anticipate tapping into his expertise to enhance our customer experience. Here's to a year filled with growth and collaboration!

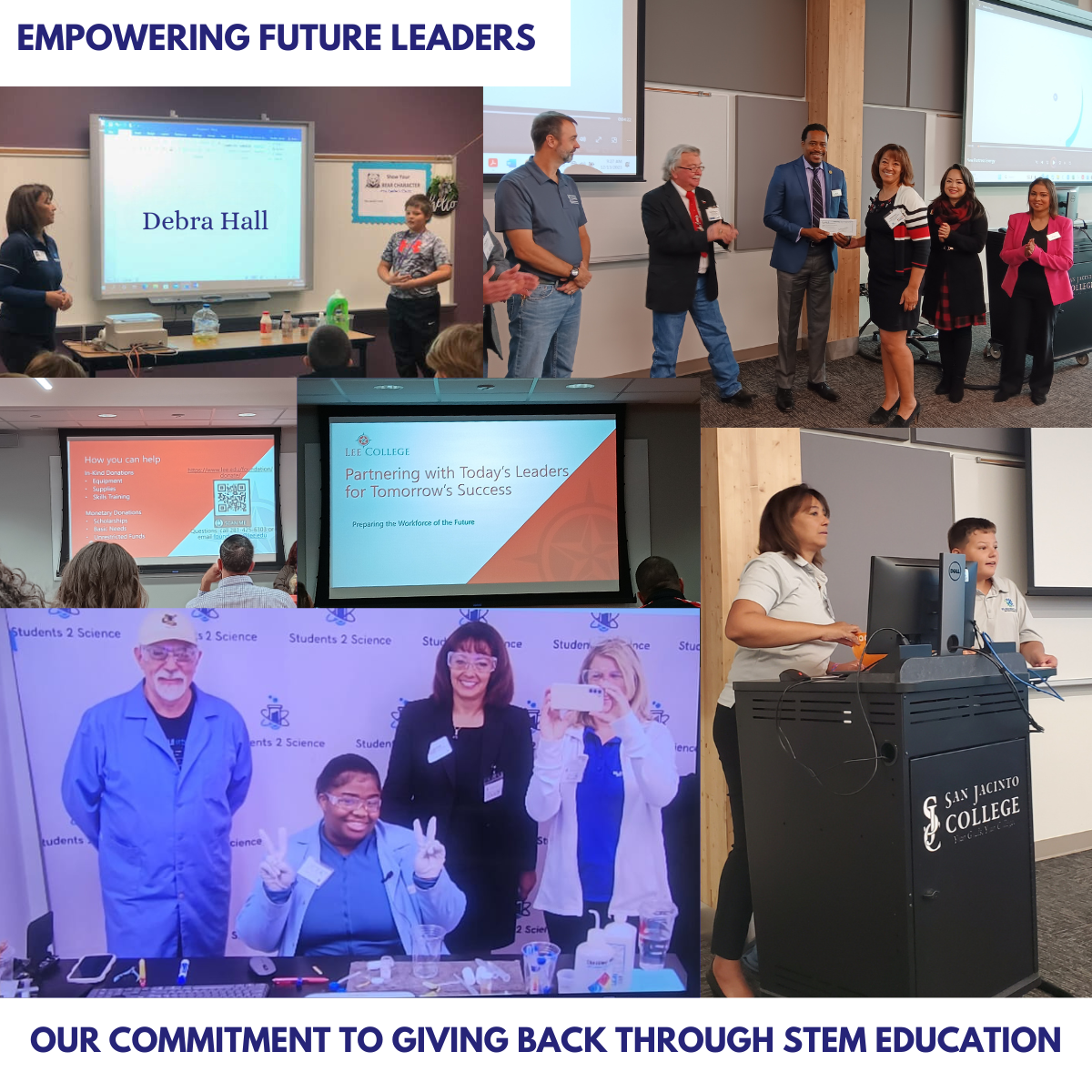

At Elementale Enterprises, we are not just a business; we are committed to shaping the future by fostering education in science, technology, engineering, and mathematics (STEM). Our dedication extends from elementary and junior high schools to college institutions, ensuring that the upcoming generations are equipped with the knowledge and resources needed to advance society's goals in sustainability while conserving energy and water for the benefit of future generations.

Here are some highlights showcasing our commitment to advancing STEM education:

Empowering Students at Lee College –

Elementale is proud to provide Lee College with cutting-edge Analytical Instrumentation. This initiative aims to empower students by offering hands-on experience with state-of-the-art online process analyzers, preparing them for real-world challenges in energy management.

Investing in Future Leaders with Greater Houston Industrial Group –

In collaboration with the Greater Houston Industrial Group, Elementale has contributed to a scholarship donation to the San Jacinto College Foundation. This scholarship is earmarked for students in the industrial arena, enabling them to develop innovative solutions for the challenges of tomorrow.

Nurturing Young Talent –

Elementale believes in nurturing the potential of young STEM enthusiasts. We have invited a promising STEM student to work with us, providing them with the opportunity to share insights and expertise on alternate energy solutions at San Jacinto College.

Exploring Collaborations at Students2Science –

Elementale is actively engaged in fostering collaboration with Students2Science at East Hanover, NJ. Our team participated in a facility tour to explore avenues for further collaboration in educating K-12 students.

Inspiring the Next Generation at Montgomery Junior High –

Elementale takes pride in actively engaging with our community. We recently conducted a demonstration for the STEM class at Montgomery Junior High, emphasizing the significance of viscosity measurements in scientific exploration.

We are so thankful to give back and inspire young minds as we pave the way for a more sustainable future. Together, we can make a lasting impact on the educational landscape and empower the leaders of tomorrow!

We are thrilled to share a major achievement!

The projects we've undertaken in 2023 have contributed to an impressive cost savings of nearly $10 million USD in energy and fuel for industries since company inception. This success stands as a testament to the trust placed in us and the strong partnerships we've cultivated. Thank you for making this accomplishment possible through collaboration and shared commitment to excellence.

We look forward to working together in the future to further add to the energy and fuel savings!

Our team had an incredible time bonding and immersing ourselves in the latest technologies at the Plastics Recycling Show in Cleveland, OH!

After exploring cutting-edge innovations, we're excited to integrate new solutions into our mission for a sustainable future.

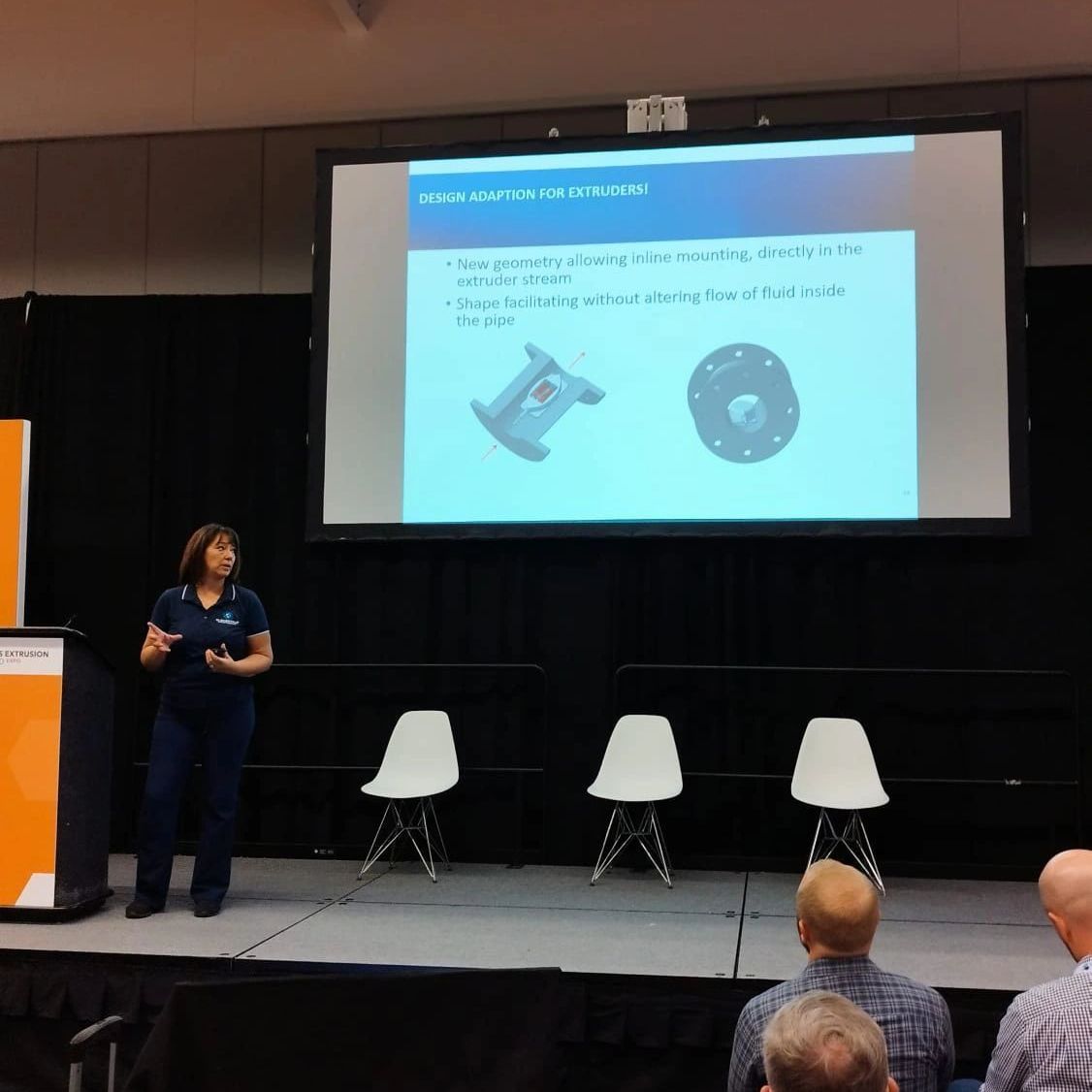

Our CEO, Debra Hall had the privilege of speaking about Sofraser's Viscosity Measurements in the Extrusion Process at the Plastic Recycling World Expo.

Debra discussed the varying properties of recycled plastic along with how crucial it is to achieve consistent online viscosity measurements.

The show had a great turnout and we're excited to assist you in every step of the process.

Elementale Enterprises is joining the Sustainability Panel of The Future of Energy at the Morris County Chamber of Commerce in Florham Park, New Jersey on November 29, 2023.

Our CEO, Debra Hall will be joining in on the intriguing discussion over cutting-edge strategies for energy transition and savings.

This is a great opportunity to connect about sustainability through leaders and like-minded business professionals.

Our CEO Debra Hall is thrilled to be speaking at the Plastics Recycling World Expo!

This presentation will discuss the best innovations in online monitoring. She’ll dive deeper into solutions offered by Elementale Enterprises specifically for viscosity control in high-viscosity polymer production.

Come listen in on the presentation, meet our team, and find out more about how we can assist you with lower operating costs and higher margins all while ensuring sustainable practices to optimize your process.

Elementale Enterprises recently had the privilege of attending the Advanced Materials Show, a dynamic event that brought together seasoned industry peers and fresh faces in the field.

The turnout was impressive, fostering engaging discussions and laying the foundation for exciting new projects. Particularly noteworthy was the insightful discussion on the Graphene Industry's considerations for novel designs. As a company that thrives on innovation, we are excited to use this expertise to bring our innovative solutions to the industry, knowing that they will have a positive effect on the development of advanced materials.

Join us at the Advanced Materials Show with CDS

Bring your colleagues and join us at the Advanced Materials Show in Columbus, OH, October 3rd - 4th at booth #914 with CDS. This event serves as a gathering point for experienced professionals to source the latest technology for applications, including Aerospace, Defense, Automotive, Semiconductors, Batteries, Electronics, and Energy.

Elementale Enterprises takes pride in offering value-added sustainable engineering solutions to industrial and commercial realms. Our goal is to reduce energy and conserve water while ensuring top performance. Our solutions are designed to elevate safety standards, streamline costs, and enhance overall competitiveness. We look forward to seeing you at the show!

Elementale Enterprises attended the Hydrogen Tech Expo at NRG Center in Houston, Texas, June 28-29.

We shared how our thermal processing solutions can help save you money on energy, stay competitive, and use new and innovative technology to make use of Hydrogen for fuel attainable.

Additionally, Debra Hall, CEO, presented a paper on innovations in Thermal Processing using H2 as Fuel Source. She discussed incorporating hydrogen fuel blending to handle Combustion, Blending Analysis, and Emission Monitoring for ease of implementation in the manufacturing process.

International Forum for Process Analysis & Control (IFPAC), Washington D.C., June 2023

We're proud to be a part of the International Forum for Process Analysis & Control (IFPAC) in Washington, DC. For those that don't know, this is a huge event featuring new technologies, trends, solutions, applications, and tons of networking.

Our CEO Debra Hall had the honor of presenting the Control Instruments CalorVal BTU Analyzer to attendees and sharing how this analytical tool and other process analytical technologies can save money and create more accurate measurements.

Upcoming Conferences & Events

Save these dates! We're planning to be at some great industry conferences and events in 2023. We’ll be sharing more on our innovative process solutions to help our clients become more sustainable and competitive.

The picture shared is the Lt Governor of Louisiana, Billy Nungesser and Elementale Enterprises’ President, Debra Hall, at the amazing 2022 LNG Summit in Lake Charles, Louisana.

We look forward to attending that one again, plus all of these other upcoming conferences and events. We hope to see you at one (or more!) of these events!

The Analyzer Technology Conference in Galveston, Texas, April 2023

Elementale Enterprises, Inc. proudly attended the Analyzer Technology Conference in Galveston, Texas. It was great to see so many interested in innovations in analyzers. Our Product Manager James Tomlinson presented a paper on gas chromatography (GC) solutions and innovative NEMS technology. Plus, we had live demos of our analyzers so visitors could see our analyzers in person.

A visit to the APIX Analytics lab in France, April 2023

Elementale Enterprises Inc. had the pleasure of visiting the APIX Analytics lab in Grenoble, France recently for a sales & technical meeting.

Debra Hall (CEO) & Kim Bogerman (Business Development) learned more in-depth detail about the ChromEx systems from APIX, which are equipped with new MRT100G modules. After focused training, a laboratory tour and a deep dive into the innovative multigas analyzers systems offered by APIX, Elementale has even more knowledge about the advantages of this technology and how it will positively impact customers in Texas and worldwide.

Our partnerships with industry leaders like APIX Analytics allow us to offer clients the unique advantage of world-class sustainable engineering solutions.

Use Lower Flammable Limit Monitoring Equipment

to Improve Process Oven Efficiency

Process heating applications involving flammable solvent removal use large amounts of energy to maintain safe lower flammable limits (LFL) in the exhaust air. National Fire Protection Association (NFPA) guidelines require the removal of significant amounts of exhaust air to maintain a safe, low-vapor solvent concentration. If LFL monitoring equipment is used to ensure proper vapor concentrations, these guidelines allow for less exhaust air removal. LFL monitoring equipment can improve the efficiency of the solvent removal process and significantly lower process energy requirements.

Flammable solvents used in industrial production processes are typically evaporated in industrial ovens. Higher oven temperatures evaporate solvent vapors more quickly, allowing for faster production. Because the vapors are flammable, the exhaust air is discharged (along with the heat) to prevent the accumulation of the vapors in the oven. As the oven temperatures increase, plants have to maintain higher ventilation ratios to reduce the solvent vapor concentration levels and maintain the respective LFL.

For example, the NFPA ventilation safety ratio for batch-loaded ovens operating below 250oF is 10:1 and xylol has an LFL of 1%. Therefore, exhaust ventilation needs to be added to the vapor until the solvent concentration reaches 0.1%, meaning that the plant has to exhaust 10 times the amount of air required by the process to meet the NFPA requirement. If the process operates above 250oF, the required safety ratio rises to 14:1, the LFL goes down to 0.07%, and the plant has to exhaust 14 times the amount of air required to keep the process from becoming flammable.

The non-uniform rate of solvent vaporization is one of the reasons why LFLs are so stringent. Solvent vaporization is inherently non-uniform mainly because of wall losses and load characteristics; this causes periodically high solvent concentrations in the oven during the vaporization process. As a result, safe ventilation ratios are calculated using the theoretical peak needs of ventilation based on the highest vapor concentrations that can accumulate during the vaporization process.

LFL Monitoring Equipment

LFL monitoring equipment can reduce energy used in solvent removal by adjusting the ventilation ratio according to the fluctuations in vapor concentration. The equipment continuously tracks the solvent extraction rate in real time and controls the rate of ventilation air based on real needs, thereby maintaining a safe ratio throughout the process. LFL monitoring equipment can employ several technologies including catalytic systems, infrared sensors, ionization systems and combustion sensors. LFL monitoring equipment has self-check functions and uses a calibrated test gas for periodic self-calibration. Because the vaporization process depends on the intake and exhaust air, linking the LFL controller to an adjustable speed drive on the exhaust system fan can improve process efficiency even further (damper adjustments can also be used).

Example

The NFPA safety ventilation ratios are significantly lower when LFL monitoring equipment is used than when such equipment is absent. This lowers the energy requirements for the process because less air needs to be exhausted to keep the process from becoming flammable. For a continuous strip coating process requiring 46 gallons of xylol with a maximum oven temperature of 800oF and ambient air temperature of 70oF, the safety ventilation ratio is 4:1 without LFL monitoring equipment. This results in an exhaust requirement of 8,330 standard cubic feet per minute and energy consumption of 6.7 million British thermal units (MMBtu) per hour. At a cost of $8/MMBtu assuming a two-shift operation, this process costs approximately $214,000 annually. Installing LFL monitoring equipment would reduce the ratio to 2:1, halving the exhaust and energy requirements. Annual energy savings would total $107,000. With an installed cost of $12,500 for an LFL controller, the simple payback is very attractive at less than 1.5 months.

Analytical Technology Show - Galveston May 2022

A great day at the ATC Galveston event. The novel analytical technologies that we showcased have demonstrated the savings that we can save the marketplace, as well as the process management and predictive maintenance that can be realized using remote measurement technology; especially XP tablets in the field. We are excited to set the trend on ESG measurements!

4 Quick-Turn & Sustainable Solutions to Alleviate Supply Chain Issues

Sustainable solutions that offset disruptions and build resilience–and are available quickly!

2022 has been no stranger to supply chain issues. Companies prolong projects or scramble to find viable comparisons when faced with shortages or extended timelines from vendors. Yet, progress must be made.

Fight the delays, disruptions, and inconsistencies impacting business – while enhancing the ESG focus and taking strides toward sustainable processes.

Elementale Enterprises has four quick-turn sustainable product solutions to offset major disruptions, boost efficiency, and build resilience so you maintain continuity and create a competitive edge. The following products are:

- Sustainable solutions

- Available for quick turn-around

- Modernizing your existing operations

- Maintaining your delivery schedule to your customers