PROBLEM

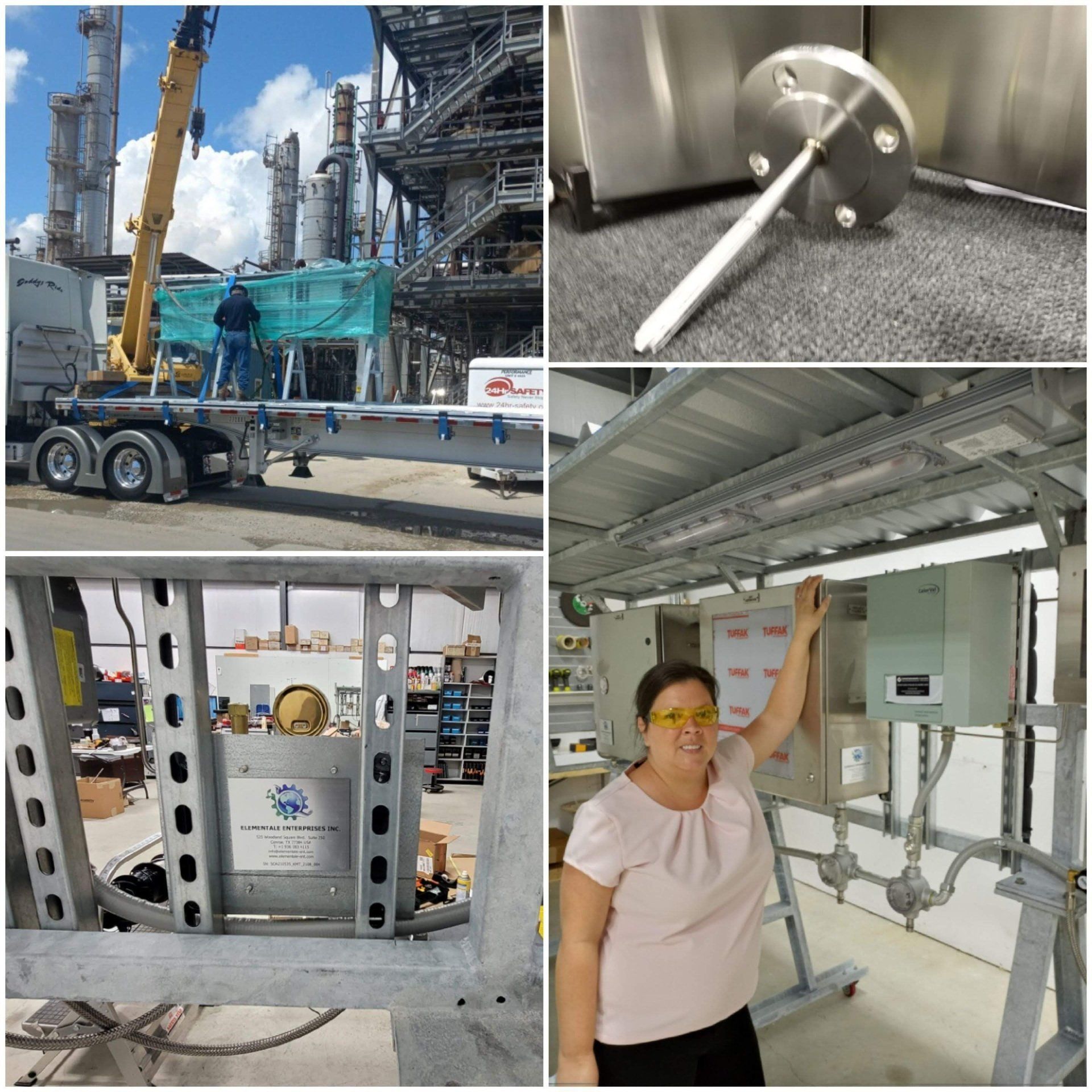

The flare was connected to multiple systems (tanks, distillation columns, pipes, etc) and would be constantly changing products. So, flexibility of the measurement system was a must to accommodate an inconsistent sample stream with primarily aromatics and glycols. The customer also needed a way to capture and record the data for their records.

SOLUTION

The customer came to Elementale to discuss how to use Control Instruments CalorVal BTU Analyzer to cost-effectively measure Total BTU content with multiple sample constituents.

In this application, high process pressures at saturated water vapor were the challenges to overcome for the customer’s selected analyzer of choice to be used.

By implementing Elementale’s unique high pressure sampling system along with our proprietary In-situ Flare Sample Probe - we were able to best accommodate the high pressure sample for accurate readings.

As the project unfolded, an added custom isolation drain/sampling system by Elementale was included to maintain continuous operation during steam down cycles. This allowed uninterrupted flare measurement even while products were changing, maintaining best-in-class requirements to the EPA standards.

SUCCESSFUL DELIVERY

The complete system has been delivered with installation by year's end. Elementale engineers will continue to provide support on an annual basis to ensure proper functioning now and into the future.